About this deal

The application process depends on the type of adhesive and the material that you are bonding the copper to.

Public Health: Properly bonded copper pipes also protect public health by ensuring that hazardous chemicals do not leach into the water supply. Ensuring that the adhesive used meets safety standards is of utmost importance when bonding copper pipes. Leak Prevention: One of the most crucial reasons for properly gluing copper pipes is to prevent leaks as it leads to costly repairs and water wastage. Even a small leak can lead to serious damage to your property if it goes unnoticed for too long. The presence of excess water and moisture can lead to the growth of molds, which can cause serious health hazards. Investing in copper pipes is like investing in peace of mind. With a lifespan that can span several decades, copper pipes require minimal maintenance and replacement, making them a cost-effective choice in the long run. Heat Conduction: Internal link: For those who have trouble gluing Traxxas tires, we have an informative guide on how-to-glue-traxxas-tires. Safety PrecautionsFire Safety: Bonding copper pipes effectively can also lower the risk of fire. Unglued or improperly bonded pipes can shift, causing voltage problems within the conduit. This can increase the chances of an electrical fire. Choosing the appropriate adhesive is crucial when it comes to gluing copper pipes together. Using the right type of adhesive can ensure that the pipes are properly joined and create a leak-free seal. There are various types of adhesives to choose from, each with their own advantages and disadvantages. Before selecting an adhesive, it’s essential to consider a few factors that may affect the outcome. By making an informed decision, you can guarantee a successful and long-lasting joint. Types of Adhesives for Copper Pipes Step 3: After applying the cement, immediately insert the pipe into the fitting and rotate it slightly to spread the adhesive. Hold the pipe securely in place for a few seconds while the adhesive sets. So, what should you use instead? Plumbers typically turn to specialized techniques like soldering or brazing to join copper pipes. These methods involve melting a metal alloy (solder or brazing rod) onto the joint, creating a strong and permanent bond that can endure high pressures and temperatures. Expansion of Gorilla Glue and Its Potential Issues If the joint still leaks after curing, it could be due to incorrect pipe measurements or an improperly positioned fitting. Disassemble the joint and make necessary changes before reassembling and gluing the joint.

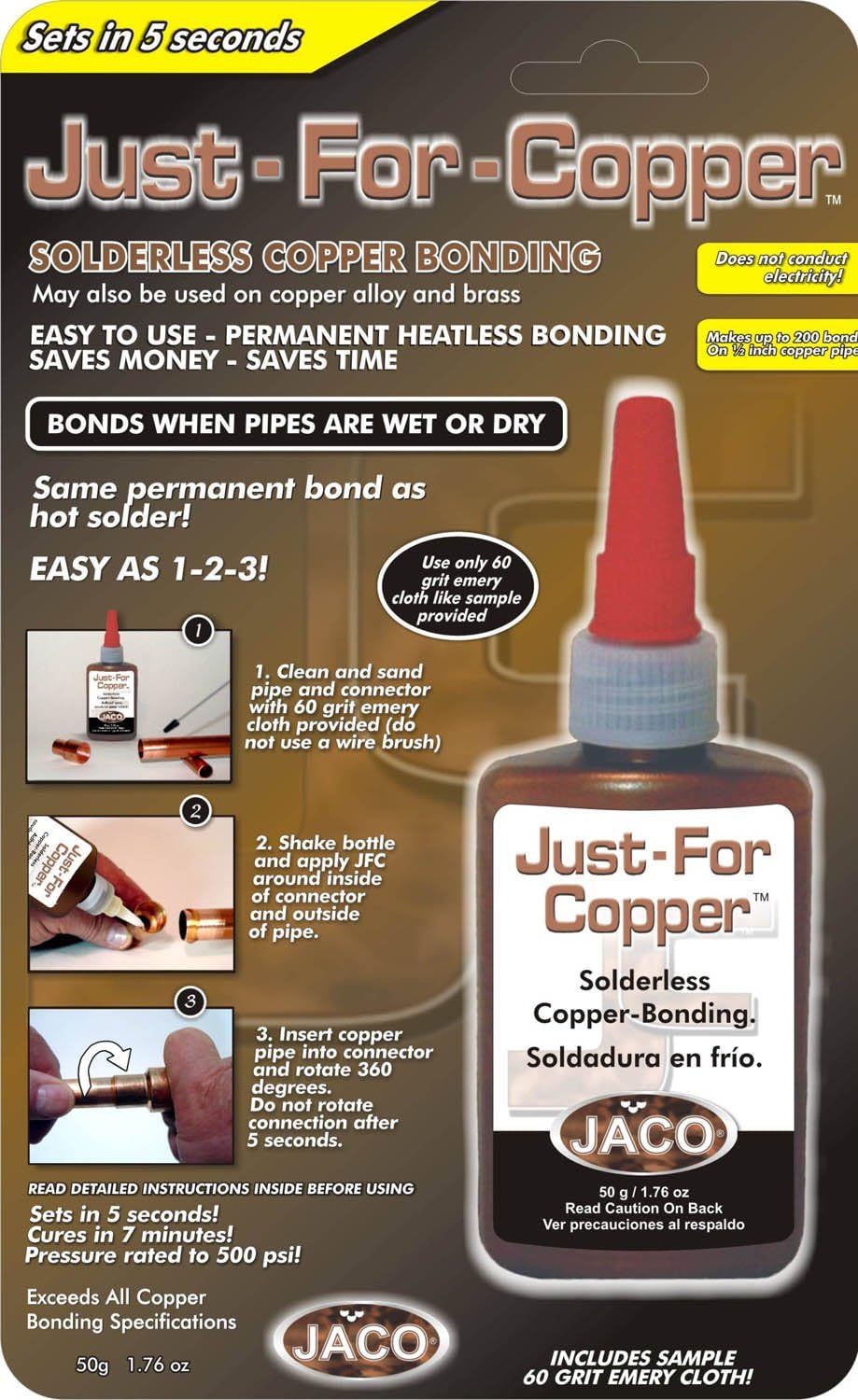

A notable feature when using shark biting fitting is the fact that you can reuse it up to 4 times. Therefore, if there’s a need for adjustment, you simply take the disconnection tong and retract the connection. Plus, shark biting offers a variety of sizes, making it very popular among DIY users and plumbers. 5. Installing thread adapters Often than not, compression fitting is highly recommended for longer connections, perhaps beyond 10 meters long. This method uses compression or plastic adapters, which then serve as the link between the two pipes. After preparing the plastic pipes, you may now get the compression nut, which is used for the copper fitting. Unscrew and slide both the nut and compression ring to the copper pipe’s end. Afterward, exert force and screw the nut to the fitting. Structural adhesives and epoxy resins are applied in two parts. With surface-activated adhesives, a resin is applied to one of the parts that you want to bond. The initiator substance is applied to the other part. With bead-on-bead adhesives, small beads of resin are applied to both parts, which are then assembled. Choose an adhesive specifically designed for copper pipes, such as soldering, brazing, or adhesive cement. Each type has its own pros and cons, so research carefully to determine which one will work best for your needs.

How to Glue Copper – Guide to Gluing Copper with Adhesives

Even with the differences, both PVC and copper pipes top off their corresponding categories. Therefore, some opt to combine these two, either for their functionality or due to material limitations. And if you plan to do so, there are certain things and other key information that you should comprehend in advance. What are some crucial aspects you need to know beforehand? Gorilla Glue is a polyurethane adhesive that expands when exposed to moisture, capturing DIY enthusiasts’ attention with its versatility. Designed for industrial-grade bonding across various materials – from wood and metal to ceramics and foam – this adhesive has earned its place in the spotlight. But can it truly hold up in the demanding world of plumbing?

Step 4: Repeat the process for all the remaining pipes and fittings, gradually putting your system together. Apply adhesive to the end of the copper pipe: Apply a generous amount of adhesive using the applicator brush that comes with the cement. Immediately insert the copper pipe into the fitting and give it a quarter turn. Some bonds provide outstanding impact resistance, while others make the application and curing easier. The main types of bonds that you should use: When applying the adhesive, make sure to apply the primer and cement in the right sequence, and to use the right amount to avoid over or under application. Assemble the pipes and fittings with gentle pressure and allow ample time for curing. It is important to prioritize safety when working with any kind of adhesive, and gluing copper pipes is no exception. Before beginning any work, make sure that you have gathered all necessary safety equipment and that each item is properly fitted and functioning. Some protective gear that you should consider includes:

23 Comments

Instead of relying on Gorilla Glue, it is wise to seek professional assistance when joining copper pipes. Plumbers employ specialized techniques like soldering or brazing, which create strong and permanent bonds capable of withstanding high pressures and temperatures. Imagine a world without functioning plumbing systems. It’s a nightmare, right? Well, we have copper pipes to thank for keeping our water flowing smoothly and our drains clear. These unsung heroes of plumbing may not get the attention they deserve, but their countless benefits and versatile uses make them an indispensable part of any plumbing system. Let’s dive into the world of copper pipes and explore why they are the go-to choice for plumbers and homeowners alike. Water Supply Lines: Step 1: Apply primer to the surfaces where the adhesive will be applied. This helps to remove any dirt, debris or grease that may interfere with the bonding process. Use a clean rag to wipe off any excess primer. Allow the primer to dry for a few seconds before applying the cement.

Great Deal

Great Deal